WELD NECK FLANGES (WNRF)

Type of Flange With High Quality in Saudi Arabia

Materia: Carbon steel: A105, SS400, SF440 RST37.2, S235JRG2, P250GH, C22.8, Stainless Steel: F304 F304L F316 F316L 316Ti, Copper etc.

Size: 1/2″ (15 NB) to 48″ (1200NB)

Leading Manufacturer of Weld Neck Flanges in Saudi Arabia, where precision meets durability. Our Weld Neck Flanges are engineered to perfection, ensuring optimal performance and reliability in a multitude of industrial applications. As prominent Weld Neck Flanges manufacturers, suppliers, and exporters in Saudi Arabia, we take pride in delivering products that exceed industry standards.

Our state-of-the-art manufacturing facility in Saudi Arabia is equipped with cutting-edge technology and operated by a team of skilled professionals dedicated to producing Weld Neck Flanges of the highest quality. We adhere to stringent quality control measures throughout the production process, ensuring that each flange meets or exceeds international standards. With a commitment to excellence, our Weld Neck Flanges are renowned for their precision, durability, and flawless finish.

Manufacturers of Weld Neck Flanges in Saudi Arabia

Our state-of-the-art manufacturing facility in Saudi Arabia is equipped with cutting-edge technology and operated by a team of skilled professionals dedicated to producing Weld Neck Flanges of the highest quality. We adhere to stringent quality control measures throughout the production process, ensuring that each flange meets or exceeds international standards. With a commitment to excellence, our Weld Neck Flanges are renowned for their precision, durability, and flawless finish.

Suppliers of Weld Neck Flanges in Saudi Arabia

As trusted Weld Neck Flanges suppliers in Saudi Arabia, we understand the importance of timely and efficient deliveries. Our extensive inventory ensures that you receive the required flanges promptly, minimizing downtime and keeping your operations running smoothly. Whether you need standard or customized Weld Neck Flanges, we have the flexibility to meet your unique specifications.

Exporters of Weld Neck Flanges from Saudi Arabia

Our commitment to quality extends beyond borders, making us reputable Weld Neck Flanges exporters in Saudi Arabia. We have successfully established a global presence by delivering our top-notch products to clients around the world. Our export operations are characterized by reliability, efficiency, and a commitment to meeting international standards, making us the preferred choice for Weld Neck Flanges.

Material & Grades of Weld Neck Flanges (WNRF) :

Stainless Steel Weld Neck Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Weld Neck Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel Weld Neck Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 Low Temperature Carbon Steel Weld Neck Flanges : ASTM A350, LF2, LF3

Alloy Steel Weld Neck Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 Copper Alloy Steel Weld Neck Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy Weld Neck Flanges :

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

ASME B16.5 Raised Faced Weld Neck Flanges Available Types

| Weld Neck Raised Face Flange | Raised Faced Weld Neck Flanges |

| ANSI B16.5 Weld Neck Flanges | Weld Neck Flange Dimensions |

| ASME B16.5 WNRF Flanges | ANSI B16.5 Class 150 Weld Neck Flanges |

| Stainless Steel Weld Neck Flanges Suppliers | SS Weld Neck Flange |

| Weld Neck Plate Flanges Dealer | ASME B16.47 Series A and B WNRF Flanges Exporter |

| ANSI B16.5 class 150 WNRF Flange Stockholder | ANSI 150 Weld Neck Flange Distributors |

| Carbon Steel Weld Neck Flange | High Quality WNRF Flanges Manufacturer |

| ASTM A182 Stainless Steel WNRF Flange | Duplex Steel Weld Neck Flange |

| Super Duplex Steel Weld Neck Forged Flange | Copper Nickel Weld Neck Pipe Flanges |

| High Nickel Alloy WNRF Flanges | Hastelloy Flat Faced Weld Neck Flanges Stockist |

| Titanium ASME B16.47 Series A and B WNRF Flanges | Inconel Weld Neck Flanges |

Key Features of Mcneil's Weld Neck Flanges

Precision Engineering: Our Weld Neck Flanges are meticulously crafted to ensure a perfect fit and optimal performance in various applications.

Durability: Built to withstand extreme conditions, our flanges are known for their durability and longevity

Versatility: Our extensive product range caters to diverse industry needs, offering a wide selection of sizes, materials, and configurations.

Compliance: Our Weld Neck Flanges comply with international standards and specifications, ensuring reliability and safety in all applications.

Customization: Tailored to your specific requirements, we offer customized Weld Neck Flanges to meet the unique demands of your projects.

Choose us for Weld Neck Flanges that guarantee performance, reliability, and longevity. Contact us today to discuss your requirements and experience the excellence that sets us apart in the industry.

Technical Parameters

Size

Application

Technical Parameters

Size

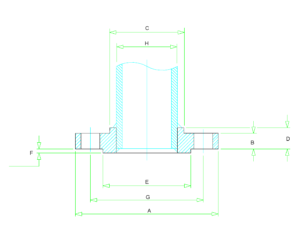

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Refer Note | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Note: Welding Neck bore is derived from the pipe schedule

Application

ANSI B16.5 Weld Neck Flanges Application

ASME B16.5 Weld Neck Flanges are known to deliver exceptional performance and are generally developed for

meeting the demands. We oer a broad range of Flat Faced Weld Neck Flanges through a worldwide network of

stock-keeping branches.

This Weld Neck Flange is used in various industries like :

This Weld Neck Flange is used in various industries like :

- Stainless Steel Weld Neck Flanges uses in Oil and Gas Pipeline

- Weld Neck Raised Face Flanges uses in Chemical Industry

- Alloy Steel WNRF Flanges uses in Plumbing

- Flat Faced Weld Neck Flanges uses in Heating

- Weld Neck Pipe Flanges uses in Water Supply Systems

- ANSI B16.5 Weld Neck Forged Flanges uses in Power Plant

- Weld Neck Plate Flanges uses in Paper & Pulp Industry

- Weld Neck Flange uses in General Purpose Applications

- Steel Weld Neck Flanges uses in Fabrication Industry

- Weld Neck Flange uses in Food Processing Industry

- Weld Neck Flanges uses in Structural Pipe

Why Choose Us?

- You can get the perfect material according to your requirement at the least possible price.

- We have many years of experience in this field as we serve the highest level of quality.

- The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

- e-guarantee to give a response within 24hours(usually in the same hour)

- You can get stock alternatives, mill deliveries with minimizing manufacturing time.

- We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.