MANIFOLD VALVE

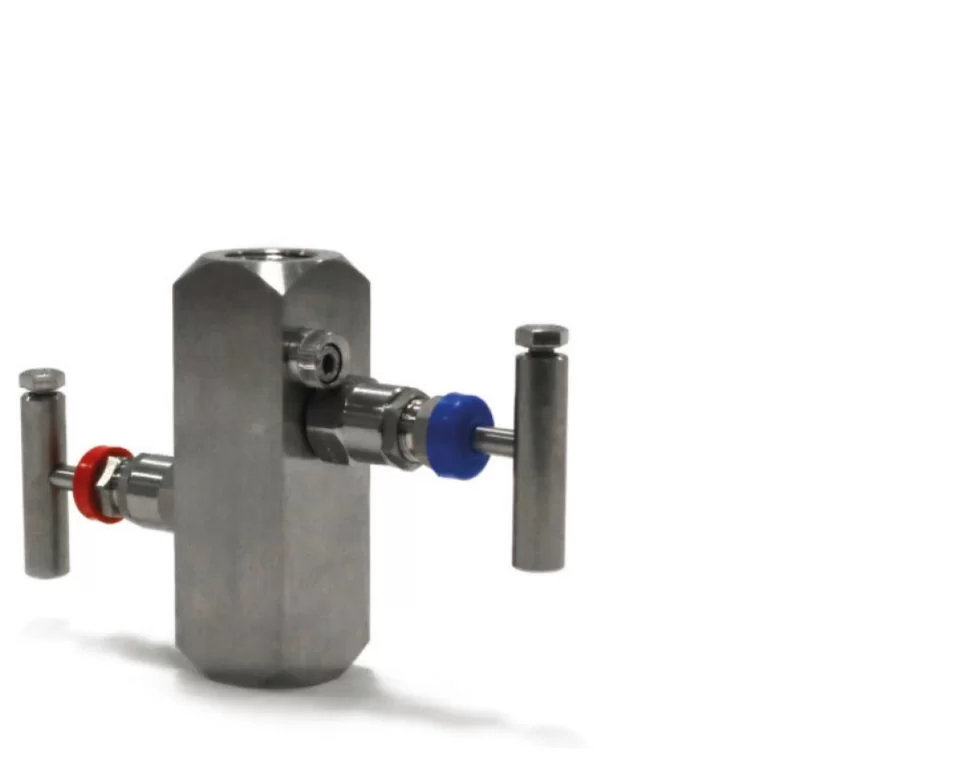

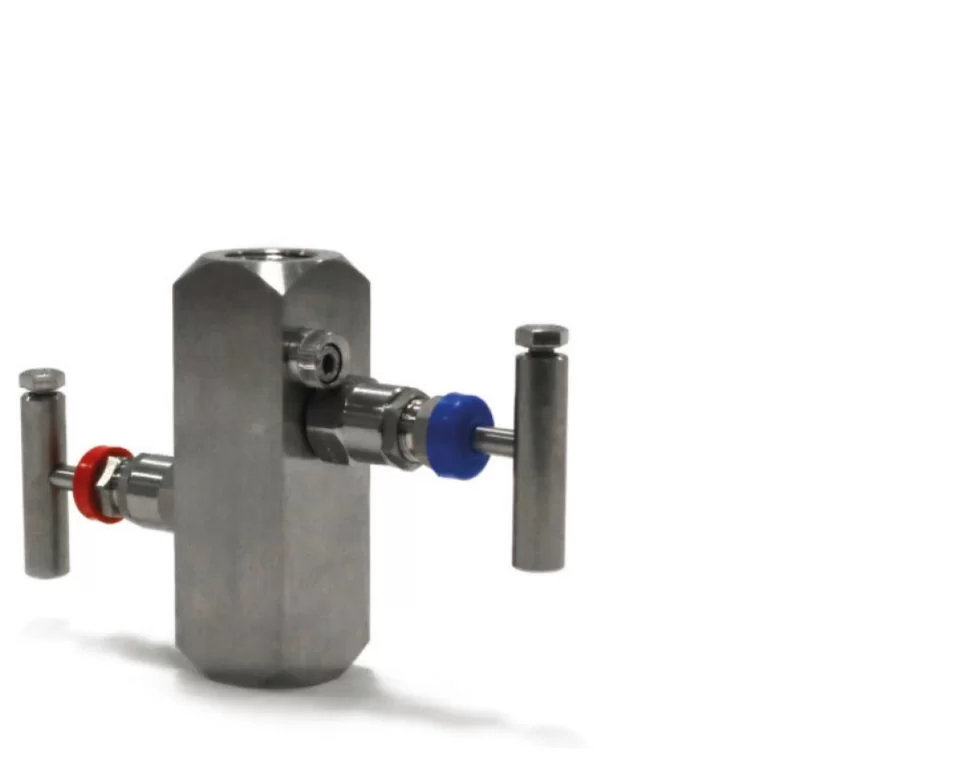

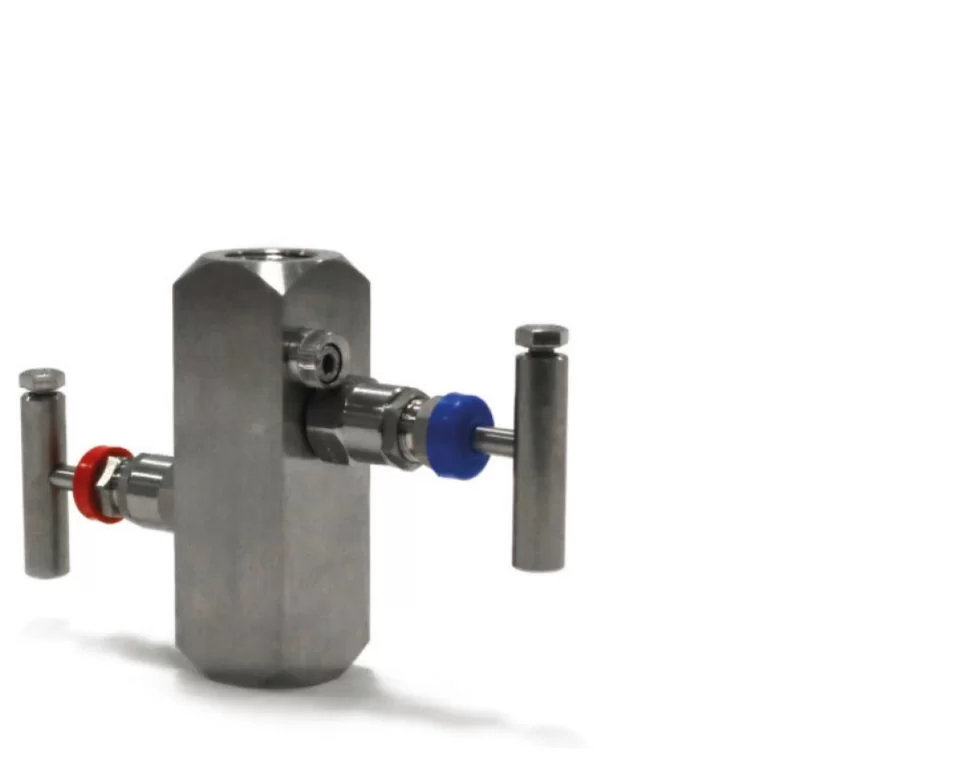

2 VALVE MANIFOLD PIPE TO PIPE STRAIGHT TYPE

Manifold Valves Manufacturer, Suppliers, and Exporters in Saudi Arabia

Mcneil Saudi Arabia offers a diverse range of 2 Valve manifolds designed specifically for static pressure and liquid level applications. These manifolds come in both traditional and compact body designs to cater to various preferences and requirements. The manifold connections are available in female tube fittings, pipe ends (NPT and ISO 228/1), and flanges (MSS SP-99) in 1/2 and 3/4 inches as well as 12 mm sizes.

As a trusted name in the industry, Mcneil has built a reputation for manufacturing and supplying high-quality valves, fittings, and industrial couplings with adapters. The company has successfully served a wide array of industrial sectors, providing products that adhere to industry-standard requirements. Mcneil’s commitment to precision design ensures not only the safety of systems but also enhances overall efficiency. Whether it’s valves, fittings, or couplings, Mcneil delivers reliable solutions that meet the needs of diverse industrial applications.

Types of Two Way Manifold Valves

Type 2VR / U2VR

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

In gauge and static instrument applications, such as pressure switches, pressure transmitters, and manometers, the 2-valve isolating and venting manifold is typically employed.

Type 2VG / U2VG

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

The ‘2VG’ Series 2 valve gauge manifold provides regulated venting and single process isolation. There are male inlet and female outlet connections available for the “2VG” Series.

Type 2VBD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Use pressure transmitters with the 2-valve direct mount manifold. The manifold will separate the instrumentation from the process and enable venting for calibration or removal from the circuit without impairing the process, application, recovery of a sample, etc.

Types of Three-Way Manifold Valves

Type 3VR

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Use pressure transmitters with the 2-valve direct mount manifold. The manifold will separate the instrumentation from the process and enable venting for calibration or removal from the circuit without impairing the process, application, recovery of a sample, etc.

Type 3VBD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

3-valve direct mount manifold with pipe connection from instrument mount. offers two isolation valves and one equalizing valve for use with static instruments or differential pressure transmitters.

Type 3VD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

3-valve manifold with direct mount, pipe connection to instrument mount. Its ‘T’ section body provides a suitable space envelope between the process lines and the instrument. One equalizing valve and two isolation valves are available in the “3VD” Series.

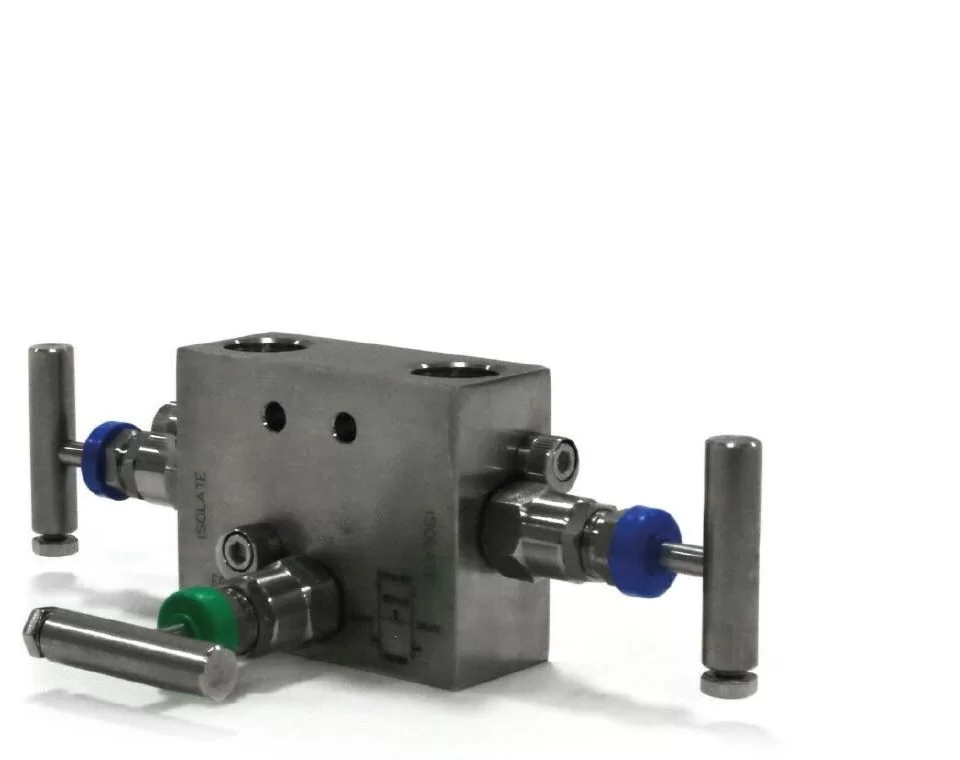

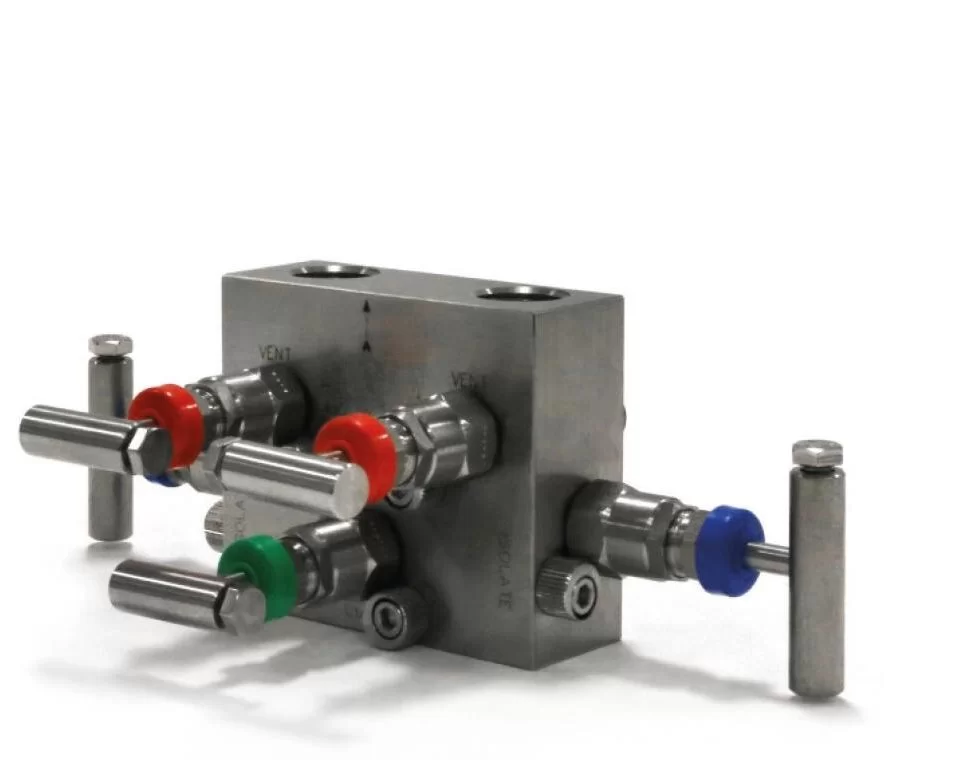

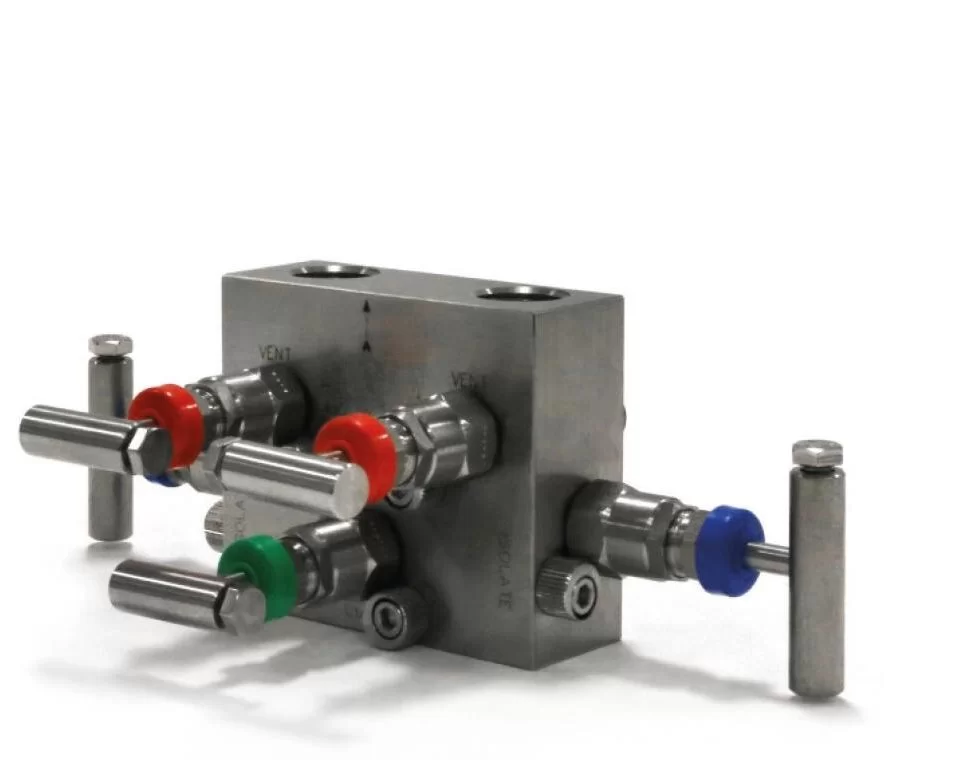

Types of Five-Way Manifold Valves

Type 5VR

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

Pipe to pipe, remote-mounted, five-valve manifold. offering two isolation valves, two vent valves, and one equalizing valve in an oil variant. used in static instrument applications and differential pressure transmitters.

Type 5VBD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

5-valve manifold mounted directly to a block with an instrument mount to pipe connection. offering two isolation valves, two vent valves, and one equalizing valve in an oil variant. used in static instrument applications and differential pressure transmitters.

Type 5VD

| Connection Size | 1/4″ – 1/2″ |

| Pressure Rating | 6000 – 10,000 psi |

| Temp. Range | -40°C up to 230°C |

5-valve direct-mount manifold with pipe connection from instrument mount. offering two isolation valves, two vent valves, and one equalizing valve in an oil variant. A ‘T’ section body format enables a sufficient distance between the instrument and process lines.

2 Way Manifold Valve | 3 Way Manifold Valve | 5 Way Manifold Valve

Manifold valves manufactured in Saudi Arabia are used for liquid level, static pressure, and differential pressure. They have fewer potential leaks and are easy to install and maintain. Three different configurations of manifold valves are available: two-way, three-way, and five-way. The Manifold Check Valve’s smaller size and reduced weight can be attributed to its compact assembly design. The following characteristics of manifold valves are easy of use, leak resistance, and long life service.

What are Manifold Valves?

Manifold valves play a crucial role in fluid control systems, serving as essential components in various industries. These valves are designed to streamline the flow of liquids or gases by combining multiple inputs into a single output or vice versa. Mcneil Saudi Arabia’s manifold valves are engineered with precision to ensure optimal performance, reliability, and longevity.

Manufacturer of Manifold Valves in Saudi Arabia

Mcneil Saudi Arabia distinguishes itself as a renowned manufacturer of manifold valves, embodying a commitment to precision engineering and quality craftsmanship. Our manufacturing process revolves around the utilization of latest technologies and robust materials, ensuring the production of manifold valves that meet the highest industry standards. Meticulous attention to detail and stringent quality control measures underscore our dedication to delivering products that stand the test of time, providing unmatched reliability and performance in fluid control systems.

Supplier of Manifold Valves in Saudi Arabia

As a trusted supplier of manifold valves, Mcneil Saudi Arabia takes pride in fostering seamless partnerships with diverse industries. Our role as a supplier extends beyond the mere transaction of goods to encompass a commitment to meeting the unique demands of our clients. With a comprehensive inventory and efficient distribution network, we ensure the timely delivery of manifold valves to businesses across various sectors. Our focus on customer satisfaction and flexibility in meeting specific requirements positions us as the preferred supplier for those seeking reliable and tailored fluid control solutions.

Exporter of Manifold Valves in Saudi Arabia

In the realm of manifold valve exports in Saudi Arabia, Mcneil Saudi Arabia stands as a beacon of excellence. Our status as an exporter is rooted in a global outlook, where we transcend geographical boundaries to bring our superior products to an international clientele. Rigorous adherence to international standards, coupled with a streamlined logistics infrastructure, enables us to export manifold valves seamlessly. As an exporter, Mcneil contributes to the efficient functioning of industries worldwide by providing them with top-tier fluid control solutions that align with global standards and expectations.

Applications of Mcneil's Manifold Valves in Saudi Arabia

- Oil and Gas Industry: Mcneil’s manifold valves find extensive use in the oil and gas sector, facilitating the control and distribution of fluids in drilling, production, and transportation processes.

- Chemical Processing: Industries involved in chemical manufacturing benefit from the precision and reliability of Mcneil’s manifold valves in handling corrosive and hazardous substances.

- Petrochemical Plants: Manifold valves play a crucial role in petrochemical plants, where they ensure the smooth and controlled flow of various fluids during different stages of production.

- Power Generation: Mcneil’s manifold valves are employed in power plants to regulate the flow of steam, water, and other media, contributing to efficient energy generation.

- Water Treatment: Municipalities and industrial facilities utilize manifold valves for controlling the flow of water during treatment processes, ensuring the delivery of clean and safe water.

Applications

Key Features

Bonnet Assembly

Technical Specification

Material of Construction

Testing

Lubrication

Applications

- Chemicals industry

- Fats and fertilizer industry

- Ship building

- Construction industry

Key Features

- Some of the key features of our superior quality high precision manifold valve design are Units duly designed to withstand system static pressure.

- The manifold valves are manufactured to endure all differential pressure and liquid level application needs.

- Units have been manufactured according to a compact assembly design. This translates into complete products which have a reduced weight and size.

- The design and manufacturing details of the valve manifold units ensure fewer chances of potential leak points.

- All units undergo extensive testing procedures to assess quality and precision before being supplied to customers.

- Units are available in a stainless steel 316 material series design.

- The units have been manufactured to ensure easy installation and hassle free maintenance in aggressive industrial systems.

Bonnet Assembly

- Bonnet : back seated blow out proof.

- Spindle : ground and thread rolled. Packing below thread.

- Spindle Tip : non-rotating tip shut-off type & soft seated.

- Dust cap : dust cap protects stem threads from external contamination heat code traceability.

Technical Specification

- Size : 1/4″ & 1/2″ & 3/4″

- Custom size available as per requirement

- End Connection : NPT, BSPT, BSP & Socket Weld.

- Working Pressure : 6000 psi (413 bar)

- Temperature Rating : PTFE 450° f(232°c)

- Grafoil 700° f (371°c”)

- Optional sour gas service valves are available confirming to nace mr-01-75

Stem Packing : PTFE, Grafoil. - Orifice : ø4.7

- All valves are 100% factory tested prior to shipment.

Material of Construction

Monel :

Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19

Testing

- Pneumatic seat test is performed at 1/4 of working pressure. Hydrostatic shell test is performed at 1.5 times the working pressure optional test are available upon request.

Lubrication

- Molybdenum disulphide (mo s2)

Why Choose Us?

- Mcneil’s manifold valves are built with durable materials to withstand extreme conditions, ensuring longevity and minimal maintenance.

- Each valve is crafted with precision, guaranteeing accurate control and regulation of fluid or gas flow in critical processes.

- Our manifold valves are designed with a focus on leak prevention, providing a secure and reliable solution for fluid handling systems.

- Mcneil offers a range of customization options, allowing clients to tailor manifold valves to their specific requirements.