LAP JOINT FLANGES STOCKIST IN SAUDI ARABIA

A quick primer on how lap joint flanges function, why you might choose them, and common alternatives available.

Welcome to the hub of Lap Joint Flanges – your one-stop destination for top-quality flange solutions in Saudi Arabia. As a leading manufacturer, supplier, and exporter, we take pride in offering a comprehensive range of Lap Joint Flanges designed to meet the diverse needs of industries across the kingdom.

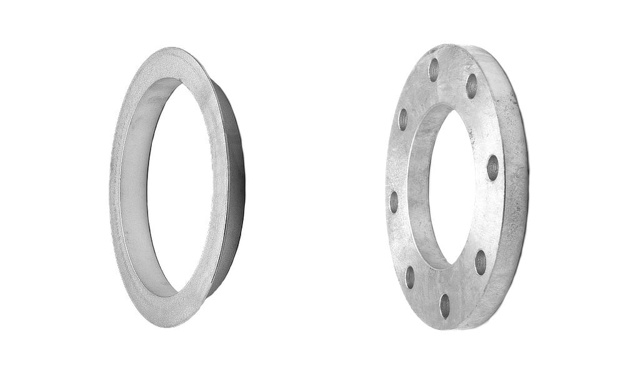

Lap Joint Flanges are unique in their design, featuring a flat face on one end and a raised face on the other. These flanges are commonly used in low-pressure applications, providing ease of assembly and disassembly. The loose, yet reliable, fit between the flanges allows for rotational alignment and flexibility.

Our Lap Joint Flanges are crafted with precision and excellence. We adhere to stringent quality standards to ensure that each flange meets and exceeds industry expectations. With a commitment to quality, our manufacturing processes incorporate cutting-edge technology and skilled craftsmanship.

Lap Joint Flanges Manufacturers in Saudi Arabia

Our state-of-the-art manufacturing facility in Saudi Arabia ensures that every Lap Joint Flange produced is of the highest quality. With a focus on innovation and efficiency, we pride ourselves on delivering flanges that stand the test of time.

Lap Joint Flanges Suppliers in Saudi Arabia

As reliable suppliers, we understand the importance of timely deliveries. Our streamlined supply chain ensures that your Lap Joint Flange requirements are met promptly, without compromising on quality. We aim to be your trusted partner in securing the right flanges for your projects.

Lap Joint Flanges Exporters in Saudi Arabia

Our Lap Joint Flanges have earned a reputation for excellence not only in Saudi Arabia but also globally. As exporters, we extend our commitment to quality to clients around the world. Trust us to deliver Lap Joint Flanges that meet international standards and specifications.

Explore the world of Lap Joint Flanges with our comprehensive solutions. As industry leaders in manufacturing, supplying, and exporting, we are here to meet your flange needs in Saudi Arabia and beyond. Contact us today to discuss your requirements and experience the difference of quality and excellence.

WHAT IS A LAP JOINT FLANGE?

Lap Joint flanges are known by several names, such as:

Back Up flanges

Loose Ring flanges

Loose Hubbed flanges

Van Stone flanges

Lap Joint Stub End and backing lap joint flange are two parts of the flange that are butt welded to the pipe and slid onto the pipe prior to the Stub End being welded.

Lap Joint flanges and Slip On flanges are extremely similar.

But only Lap Joint Stub Ends are compatible with Lap Joint flanges because they have a radius at the junction of the flange face and the bore to allow the flanged part of the Lap Joint Stub End.

To provide more cost flexibility, materials for lap joint stub ends and flanges might change even within a single installation.

Lap Joint flanges are commonly made of various alloy materials, carbon steel, and stainless steel.

These flanges are simple to incorporate into current pipe systems or use in conjunction with other piping components since they are available in typical diameters similar to other flange types.

Stub Ends also preserve the interior and outside diameters of your piping process by matching the wall schedule and pipe material. In designed plumbing systems with strict wall thickness specifications, this form is usually employed.

Depending on your demands, Stub Ends are also offered in two distinct lengths: MSS, or Short lengths, and ASA, or Long lengths, along with a variety of face finishes.

Serrated or phonograph finishes, for instance, can improve gasket adhesion.

WHAT SEPARATES ROLLED ANGLE RINGS FROM LAP JOINT FLANGES?

With identical designs and installation requirements, Rolled Angle Rings, sometimes called Vanstone Rings or Vanstone Rolled Angle Rings, have benefits that are equivalent to those of Lap Joint Stub Ends.

But in most situations, there are little distinctions that will make one better than the other. The fact that Rolled Angle Rings are not registered fittings should not be overlooked.

Similar to lap joint flanges, the two-part construction of the rolling angle ring and backing flange allows for further flexibility and possible cost savings by allowing for the use of alternative materials. Using a 316/L SS rolled angle ring with a carbon steel, galvanized backing flange is one way to illustrate this. The backing flange is also free to rotate on the pipe, allowing for easier alignment.

In contrast to Lap Joint flanges, rolling angle rings can be installed in one of two ways:

Butt-Weld

Slip-On

Butt-Weld Similar to Lap Joint Stub Ends, Rolled Angle Rings must be welded to the pipe’s end and have an inner diameter that matches the pipe or fitting that is being used. Slip-On Rolled Angle Rings are attached to the exterior of the pipe wall rather than the end of the pipe by sliding over it.

Additionally, Rolled Angle Rings are not made in accordance with the schedule of the relevant pipe or fitting.

Although bigger pipe diameters may need the usage of 7 gauge Angle Iron, they are often built using 11 gauge Angle Iron.

Certain smaller rings, which are often referred to as I.D. Pressed Vanstone Rings or Pressed Angle Rings, are formed from a plate that has been cut to precise inner and outer diameters using hydraulic pressure.

This offers a smooth ring design that’s simple to make and duplicate.

However, it is challenging to use hydraulic presses to produce Rolled Angle Rings with precise 90-degree angles.

Why Choose

Why Choose

- Durability: Crafted from premium materials, our Lap Joint Flanges are built to withstand the rigors of diverse industrial applications.

- Precision Engineering: Our commitment to precision ensures that each flange is engineered with accuracy, guaranteeing a seamless fit and optimal performance

- Versatility: Whether you need Lap Joint Flanges for petrochemical, oil and gas, or water treatment applications, our versatile range caters to diverse industry needs.

- Compliance: Our Lap Joint Flanges comply with industry standards, ensuring that your projects meet regulatory requirements.

Why Choose Us?

- You can get the perfect material according to your requirement at the least possible price.

- We have many years of experience in this field as we serve the highest level of quality.

- The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

- e-guarantee to give a response within 24hours(usually in the same hour)

- You can get stock alternatives, mill deliveries with minimizing manufacturing time.

- We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.